" Pure-white, stone-cold fiber optic lighting sytems "

Fiber Optic Lighting

What Is Fiber Optic Lighting?

Fiber optic lighting is a system. The system is made up of:

There are several lit fibers. Therefore, there are several miniature lights lit by a single lamp. Each fiber can be bare or a light.

For a NoUVIR system, there are 32 fibers. So there are 32 lights. The lights can be all be the same type or an assorted variety from floods to powerful multi-fiber luminaires to a kerosene lantern or candle. “FOL” means Fiber Optic Luminaire.

Since light travels through the fiber to each luminaire, the projector can be 10 feet or 50 feet away. The projector is remote. Each miniature, individual light is “powered” by a lit fiber using no electricity.

Where Does the Light Come From?

The light source is a projector or an illuminator.

NoUVIR uses a projector.

A projector is designed with sophisticated optics in focus to get as much light into the fiber as possible using the correct entrance angles.

This means as much light as possible exits at the other end of the fiber.

NoUVIR uses a projector.

A projector is designed with sophisticated optics in focus to get as much light into the fiber as possible using the correct entrance angles.

This means as much light as possible exits at the other end of the fiber.

An illuminator has crude or no optical control. The optics are defocused.

Often illuminators are just a box with a lamp, a hole for a bushing, maybe a dichroic filter and a fan to cool the lamp.

NoUVIR is unique in that Its COLD-NOSE® technology allows for a very tight, very bright, concentrated focus on the fiber.

A NoUVIR system is able to intensely light the fiber without heating or melting it. This is COLD-NOSE technology.

The projector’s nose holds each fiber as individuals in the fiber bushing, so design can be done on the fly on site or the system can be reconfigured in the future.

Many NoUVIR systems have been installed for a traveling exhibit or for a gallery operating for years only to later be cleaned,

checked and installed as if new for a completely different exhibit. Good fiber optic systems are long lasting and flexible in design.

Cold Light into the Fiber

A projector focusses and manipulates the entrance angles into the fiber.

Steep angles bounce more light against the side of each fiber.

The better the optical control into the fiber, the more light ends up at the luminaire.

NoUVIR is unique in that its projector produces only visible, white light. Every color is present. It provides superior color rendition.

Forget the typical lighting test of sorting navy socks from black.

With NoUVIR systems a person can tell the difference in a titanium white (slightly warm) verses a

zinc white (silver white) and the difference between a Mars black (touch of red) and an ivory black (hint of purple as raven).

Colors are warm or cool as determined by a complex palette and not tinted by the lighting. Therefore, things look awesome.

Optical Fiber Types

The projector pours light into the fibers.

The material of the fiber, how the fiber is made and the fiber’s quality determines what light makes it to the luminaire.

Fibers materials are glass or plastic.

The fiber can be “solid” (a single core as a fat fiber) or “stranded” (made up of thin, hair-like fibers glued or fused together at each end with a metal ferrule).

The different fiber materials have different characteristics. For example, glass fiber has a peak transmission for IR.

It’s easily available for lighting, but it is a communication fiber designed for IR lasers.

The different fiber materials have different characteristics. For example, glass fiber has a peak transmission for IR.

It’s easily available for lighting, but it is a communication fiber designed for IR lasers.

NoUVIR uses 100% virgin acrylic fiber (PMMA or poly methyl methacrylate) in a 1/8” diameter solid core.

Acrylic is a superior material for the transmission of visible light. But it is a difficult material for other fiber optic companies to use for two reasons.

1.) Focusing light into the fiber without COLD-NOSE technology means focusing heat into the fiber as well. Acrylic melts.

So those that use acrylic fiber defocus the lamp to control the IR. These acrylic systems have lower footcandles and work for effects.

But they have problems producing enough light to be an alternative to halogen, LEDs and fluorescent lights.

The other option is to use glass that will not melt, but does not ideally transmit visible light.

2.) Both glass and acrylic fiber are made in different grades.

But aerospace-grade acrylic fiber (the highest grade) is hard to get. NoUVIR buys special runs usually on a two-year commitment.

Acrylic fiber and other plastic fibers have a design advantage over glass systems.

The fiber can be cut and polished in the field. Glass has to be factory made. Therefore, lighting design is much easier.

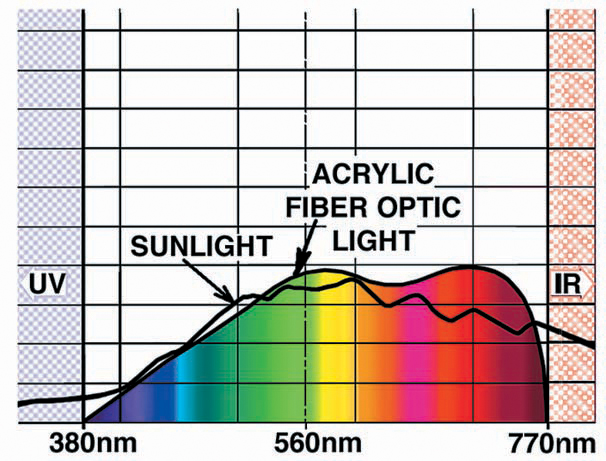

Acrylic has the ideal molecular structure for transmitting visible light. This is light from 380 nm which is a deep violet color to light that is 770 nm which is a dark red burgundy.

Why Fiber Optic Lighting?

Light below 380 nm is ultraviolet. We do not see it. And it is harmful.

It tends to break things apart internally. It will fade. But it is light that cracks, yellows and embrittles.

This is the photochemical damage that does not happen at the surface, but deep down within the object. It weakens the structure. It is how things turn to dust.

Be warned. Light from 380 nm to 400 nm is important.

If you want to see the purple majesty in mountains in a landscape or you want your skin to look healthy as

blood colors need a deep purple in the light, these colors need to be in the light source.

Be warned. Light from 380 nm to 400 nm is important.

If you want to see the purple majesty in mountains in a landscape or you want your skin to look healthy as

blood colors need a deep purple in the light, these colors need to be in the light source.

NoUVIR has no UV. But NoUVIR has all the colors.

Light above 770 nm is infrared.

We do not see it. It is also harmful.

Infrared light causes both photochemical and photomechanical damage.

It is the fading, dirt build-up, surface spalling, yellowing the top coat, blooming, discoloring damage that makes things ugly.

Basic chemistry states that for every rise in 10°C, a chemical reactions doubles taking half the time. Infrared causes photochemical damage. IR accelerates damage.

Have light above 770 nm? Fade things faster. Age things faster. Pay more in air conditioning bills.

Again, be warned. Light that cuts off before 770 nm trims red color out of the visible white light.

Things stop looking as inviting. You’ll miss the vibrancy of a Golden Retriever’s coat or the depth of a truly red apple.

NoUVIR has no IR. There is no heat. But NoUVIR has all the colors.

Lighting fiber with a projector and terminating it in another place as miniature lights lets science filter light into more and more visible light.

That is not to say fiber optic systems naturally remove all UV and all IR. They don’t. But fiber optic lighting is the only way to completely filter down to white light.

Finally, remember that different projectors and illuminators use different lamps.

If a fiber optic system uses a halogen projection lamp, it can have tight focus and all the colors.

But if a fiber optic system uses a LED lamp, it will automatically have a defused focus and a lot of blue color in the light.

An HID (high intensity discharge) lamp will be missing colors. So pay attention to the lamp. A lamp cannot create a color out of thin air and fill in a gap.

Either the lamp will have the color or it will not. Therefore, you can predict the color rendition of most fiber optic systems if you identify the type of lamp that is used.

Fiber Optic Luminaires and Heads

At the end of the fiber, the light hits air. The fiber will spread the light into a 72° beam.

Point a fiber at something and light it. Mount spaced fiber in a room or a case and light an area.

Add a reflector and lens, the fiber’s output is controlled. Luminaires is the technical term.

But some companies call the lights heads. Fiber optic lighting then matches its larger, electrified cousins by offering products in fiber optics from eyeballs to tracks.

But fiber optic lighting is unique. There is no wiring. There is no electricity.

There often is little or no heat. The lights are miniature. The lighting is easy to hide.

And frankly, unlike light fixtures with electrical hook-ups, junction boxes, heat sinks and mounts, most fiber optic lighting can

be installed without tools and safely operate in just about any material or just about any place.

Are NoUVIR Luminaires Different?

NoUVIR manufactures the only reflector made specifically for the output of a fiber.

The reflector has a high-tech, dual surface. It looks dark when viewed from an angle.

Because the fiber can be slid back and forth within the reflector, the focal length changes.

The beam zooms. It changes from a 72° beam concentrating the light brighter and brighter through smaller and smaller beam sizes to a 36° beam. This is the flood’s performance.

Add a lens to this specialized reflector and the beams can zoom further down to a 15° spot and a 5° pinspot.

NoUVIR manufactures the only macro-micro lens for fiber optics.

It makes our beams superior as they are fully adjustable, smooth from edge-to-edge, have no dark spots or fluctuation in light level and have a soft, but exacting cut off.

Add a lens to this specialized reflector and the beams can zoom further down to a 15° spot and a 5° pinspot.

NoUVIR manufactures the only macro-micro lens for fiber optics.

It makes our beams superior as they are fully adjustable, smooth from edge-to-edge, have no dark spots or fluctuation in light level and have a soft, but exacting cut off.

Other companies use reflector and lens designs from filament light fixtures.

There products may or may not zoom. All have poorer beam quality.

Some, once the beam size is determined, glue the fiber into the back of the luminaire.

NoUVIR has designed a special collet that holds the fiber, lets the zoom focus be changed over and over again,

yet it holds the focus for decades if desired and will let luminaires be swapped or interchanged.

Unlike other types of lighting, fiber optic lights can be held in a hand.

Pick up a lit light in your hand, move it around, aim it and then decide to install it just where you want.

Other roughly calculate and install. But can still put a footcandle meter in a beam and adjusted the light level.

No UV, No IR...NoUVIR

Almost all fiber optic systems made for lighting dramatically reduce the ultraviolet and the infrared content of the light.

Most fiber optic companies will state in sales literature that their systems produce only visible light.

The terms like “virtually” or “remove almost all of” only show up in the specification sheets. So get accurate data, not just sales materials.

NoUVIR is more than our name. It is a promise of no UV and no IR…NoUVIR®

Why NoUVIR Fiber Optic Lighting?

Because it is amazing technology.

You can do things like this-

This is an exhibit in a casino restaurant.

Yet this very rare costume is better protected and preserved than if it were displayed in most museums.

The dress is Judy Garland’s “test dress” from the Wizard of Oz.

There was only one test dress compared to eight film dresses.

Garland wore this the first week of test filming.

The pinafore was the right style, but failed to obscure her bust line enough to drop her age so she would be a girl for the part.

The studio redesigned the dress with gingham.

There was only one test dress compared to eight film dresses.

Garland wore this the first week of test filming.

The pinafore was the right style, but failed to obscure her bust line enough to drop her age so she would be a girl for the part.

The studio redesigned the dress with gingham.

Of course, the case contains famous Ruby Red lippers.

NoUVIR has lit a number of pair over the years.

But these are especially impressive lit at the base of a tall case.

Fiber optic lighting reaches these treasured shoes from an 18-foot ceiling.

The dress is lit at low conservation lighting levels with very little light on the fragile blouse or shoulders.

The shoes are lit from outside the case to make the shoes sparkle. Beam control is so excellent, there is no spill onto the hem.

Since the case is lit internally and the shoes are lit with 5° beams, the case turns transparent.

Reflections are a minimum.

The case is acrylic and sealed. An AIR-SAFE micro-climate control system self cleans, filters and treats the air to maintain an exacting humidity.

The projector is above the casino’s tall ceilings on a catwalk. Maintenance never opens the case.

The case is under the complete control of the curator.

Housekeeping uses special approved cleaners to protect the acrylic surface of the case, but does not have to worry about harming the artifacts.

The AIR-SAFE also keeps all contaminants including anything from patrons (like sticky skin cells) and the kitchen (cooking oils and salad vinaigrette) completely out of the case.

A humidity monitor tracks any fluctuation, but the AIR-SAFE system holds the relative humidity steady, rain or shine.

Need to learn more about the science and photons? See the pdf What Is Fiber Optic Lighting? Click Peer-Reviewed Science, top right corner of the home page.